Active Harmonic Filter Installation

Harmonic levels at a large grain storage and drying factory had, over the past few years, crept slowly up in distortion eventually leading to some major equipment failures. This increase was also having a detrimental effect on the Power Factor Equipment already installed on site. Though this was detuned PFC equipment, which is designed to prevent the capacitors from increasing the harmonics when the capacitors come into circuit, it too was struggling with the high levels of distortion on the site load.

Following a week-long Power Quality Analysis, it was concluded that the best way to reduce these harmonics would be with a 125A Active Harmonic Filter on each supply in place of the existing PFC Equipment installed in a Master/Slave configuration. The new AHF would also be able to correct the Power Factor with its built-in capacitor banks.

The new AHF Units would utilise the existing power cables feeding the PFC Equipment, and a new multi-core C.T cable would be run along with new Current Transformers on the main LV tales for the filter to see the site’s loads and correct accordingly.

Once the new filters were installed a full commissioning was carried out on by our engineers along with a connection of a remote monitoring device as standard to provide remote access to the Active Harmonic Filter from any desktop PC.

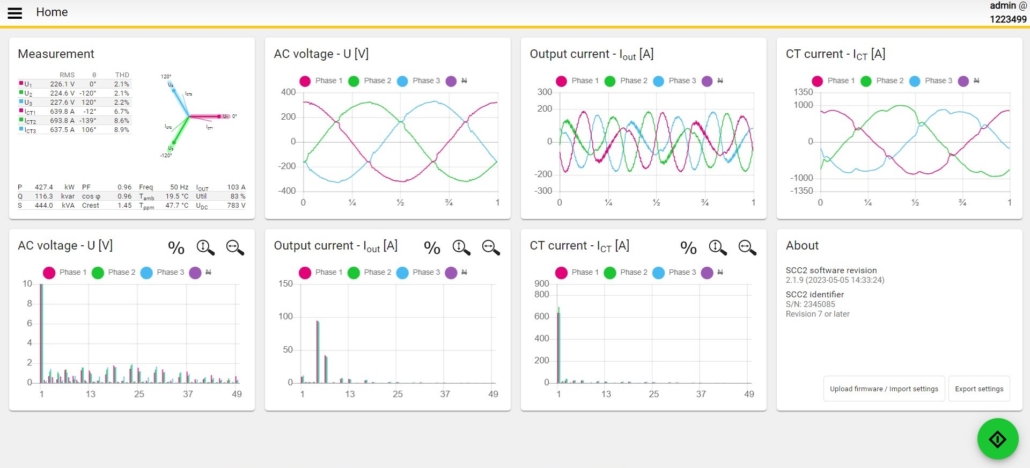

Upon completion of the works, the new AHF lowered site’s average voltage distortion down from 6% to 2% across multiple harmonic ranges and corrected the Power Factor from 0.89 inductive to 0.99 inductive.

Original Power Factor Correction Equipment on site.

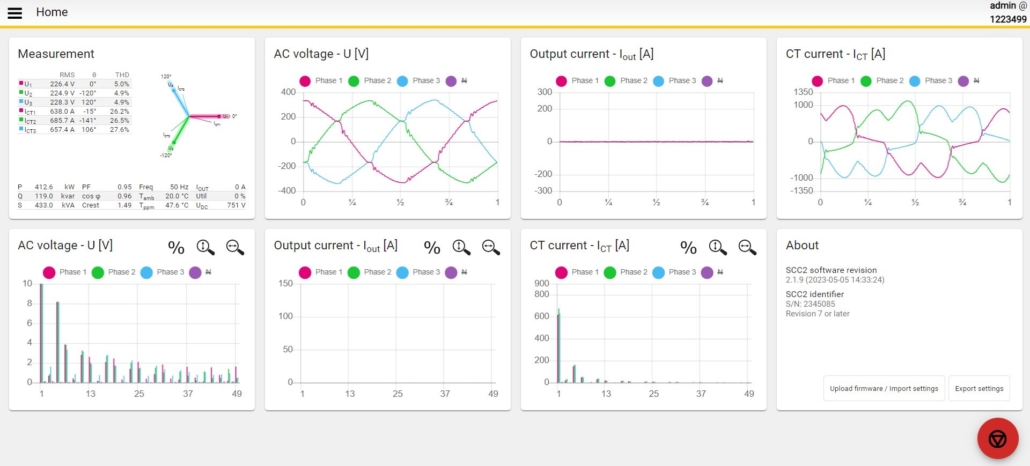

Active Filter – Off

Active Filter – ON