Following the annual maintenance at a grain mill it was found that additional capacitors were required to help the site reach a healthy Power Factor above 0.95 inductive.

The existing equipment on site was fully operational however space was very limited with the LV panel being built against the wall of the operating control room. An external door gives access to the rear of the PFC section, and it was via this that a custom framework was built to mount one of our fully shrouded 100kVAr SBA capacitor tray assemblies.

The new assembly was then wired as additional stages to the existing unit. Site are now back to a good power factor even when running at full load, helping to reduce and eliminate the reactive charges on their monthly bills.

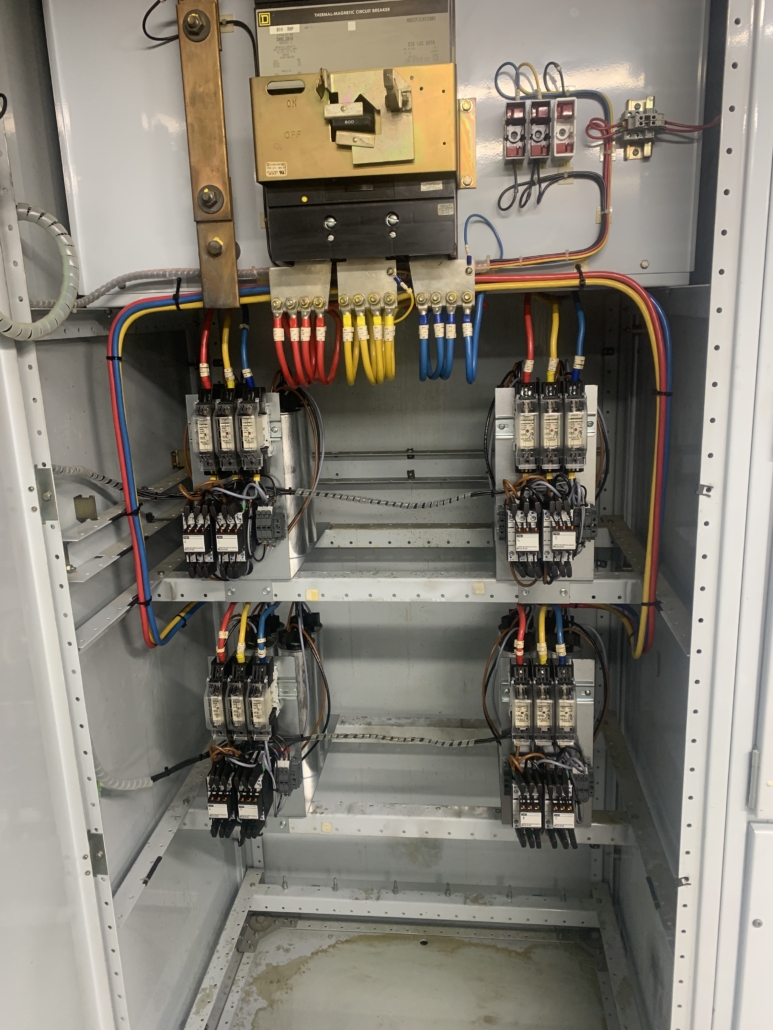

Above: Front of PFC Section.

Above: Rear of PFC Section with additional SBA tray mounted at the top